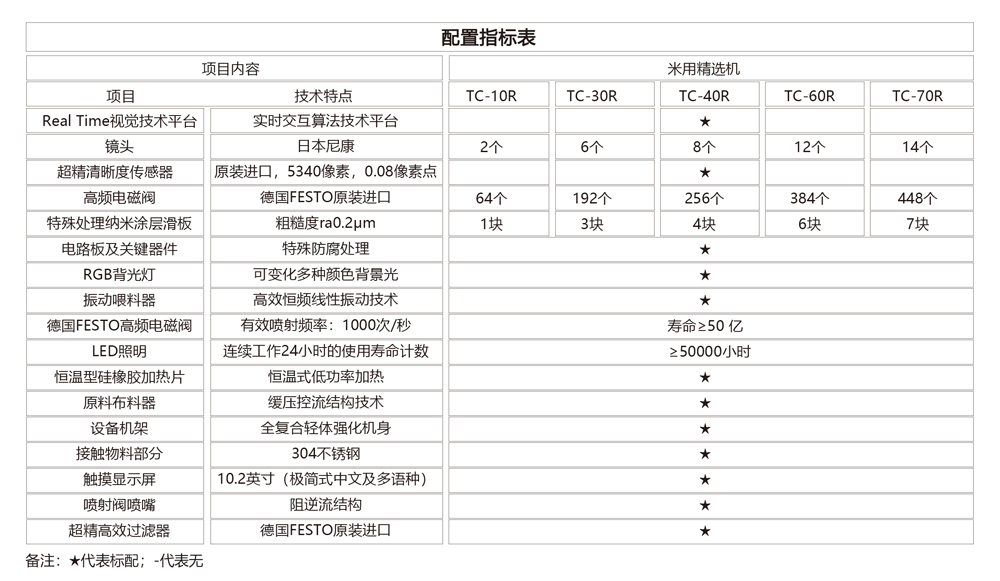

The output of rice color sorter is 50 ~ 100kg per channel, and that of wheat color sorter is 150 ~ 250kg per channel. The same 96 channel color sorter can process about 6t / h of rice and 12 ~ 15t / h of wheat. U-shaped slideway is adopted to improve the accuracy of color selection and reduce the belt out ratio. The slide is equipped with a heating plate to prevent rice bran from sticking to the slide and affecting the normal downward flow of materials. Humanized true color touch screen, clear visual effect and simple operation. The color sorter mentioned above is equipped with a ccd sensor recognition system. If a traditional sensor recognition system is configured, the effect will be much worse. Therefore, when selecting the color sorter, it is necessary to first make clear the processing object and its impurities, otherwise, the expected effect will not be achieved. In the application environment of the rice color sorter manufacturer, there are a lot of dust and dust, and the vibration and interference are also large. The change of temperature and the difference of rice and wheat quality will affect the working state of the color sorter, resulting in inaccurate detection signals or the change of the delay time for controlling the opening of the high-pressure gas valve, thus affecting the accuracy of the impurity injection action.

Download Center

Download Center Video Center

Video Center (86)0411-87625211

(86)0411-87625211