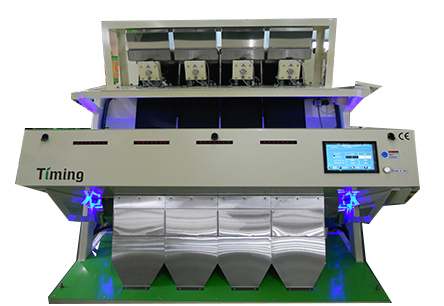

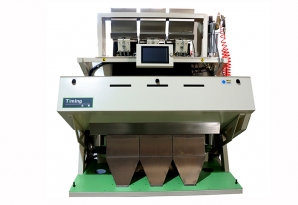

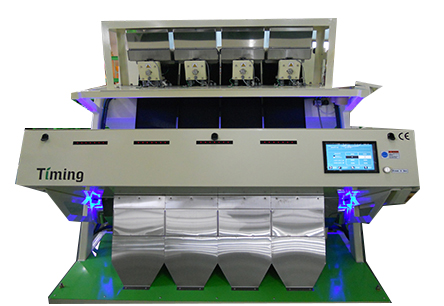

The device is an array composed of many tiny photoelectric sensors. It uses a high-quality camera dedicated high-definition lens, and usually has several to dozens of the same sensors to independently detect the materials flowing in each channel (it can be likened to a compound eye structure, while a single silicon photocell is a single eye structure). Early cereals color sorters used photocells, photodiodes, and silicon photocells to detect optical signals. Its greatest advantage was low cost, easy production, debugging, and fabrication. The subsequent signal processing circuit was simple. The matching optical system used a simple electric eye, consisting of two simple lenses, which did not require adjustment and was also low in cost. U-shaped slideway is adopted to improve the color selection accuracy and reduce the strip out ratio. The slide is equipped with a heating plate to prevent rice bran from sticking to the slide and affecting the normal downward flow of materials. Humanized true color touch screen, clear visual effect and simple operation.

Download Center

Download Center Video Center

Video Center (86)0411-87625211

(86)0411-87625211