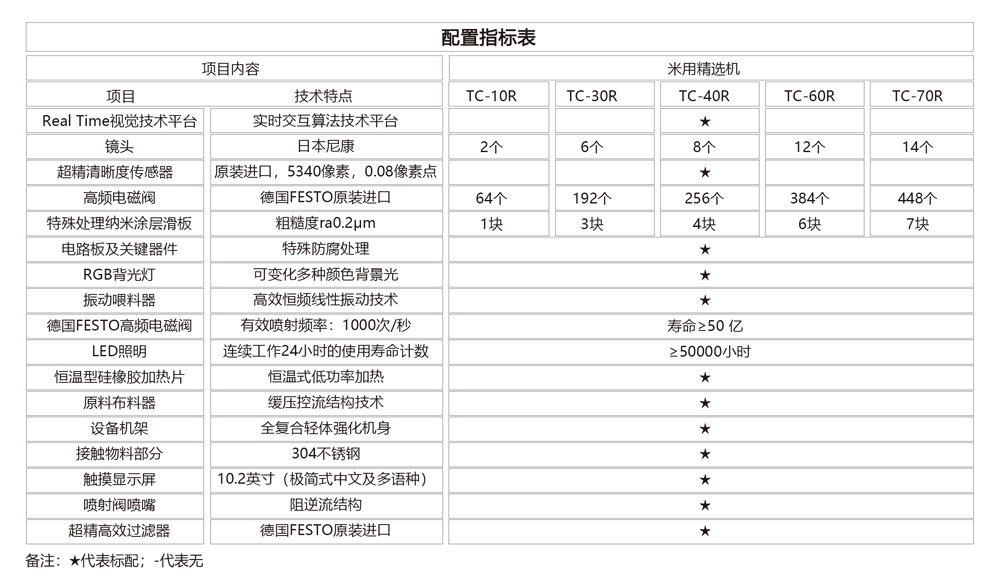

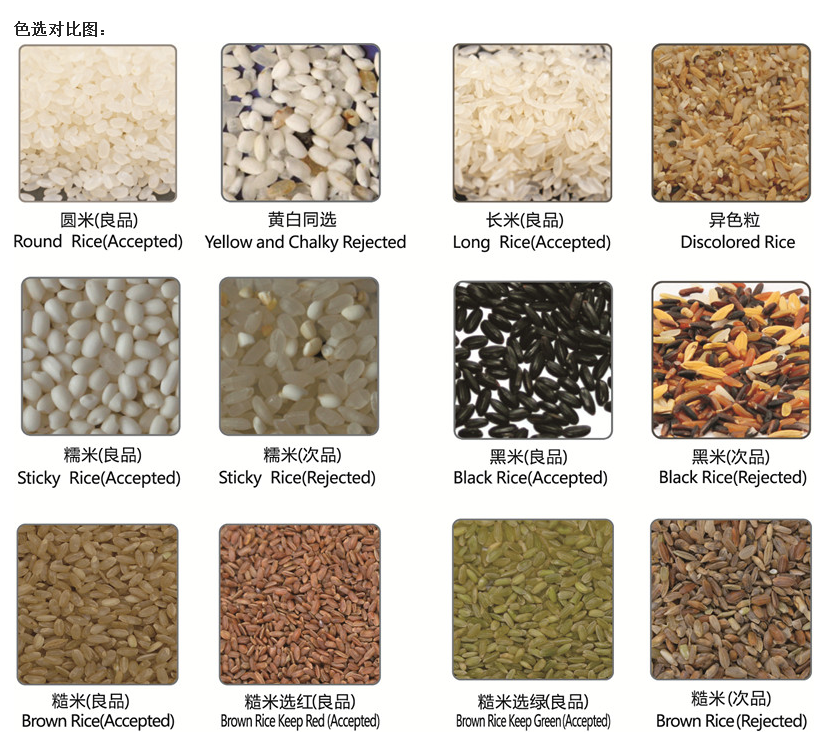

When selecting the rice color sorter, we should focus on the progressiveness of the technical performance, the reliability of the equipment quality and the long-term stability of the use of the color sorter. We should conduct comprehensive consultation and extensive comparison. Therefore, when selecting the color sorter, it is first necessary to understand the processing object and its impurity content, otherwise, the expected effect will not be achieved. According to the difference of optical characteristics of materials, it is an equipment that uses photoelectric technology to automatically sort out different colored particles in granular materials. The primary color sorter only selects the materials once, and the secondary materials contain more normal rice grains or wheat grains. Usually, when the user accumulates a certain amount, he uses the color sorter to color again, which is laborious, time-consuming and troublesome. The use of high-performance integrated blocks can greatly reduce the failure rate and save power consumption. The stainless steel receiving bin can prevent the equipment from rusting, insects and mildew caused by the moisture of rice bran. The circuit and optical components adopt a fully sealed structure to achieve a dust-free working environment and ensure the stable operation of the equipment.

Download Center

Download Center Video Center

Video Center (86)0411-87625211

(86)0411-87625211