|  |

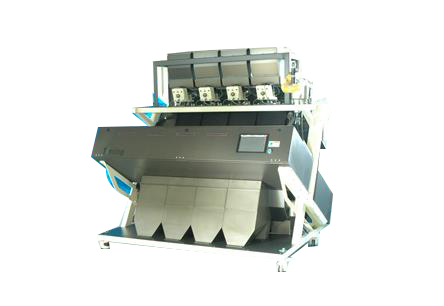

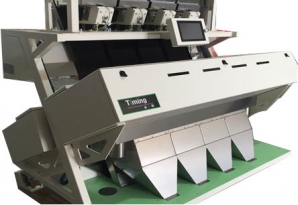

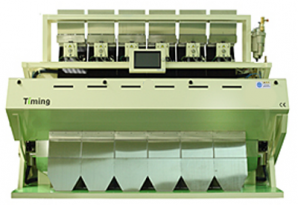

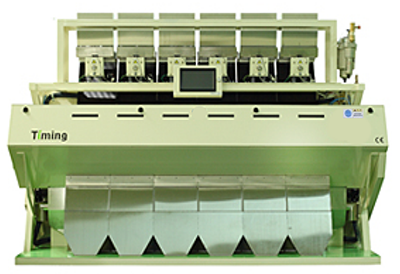

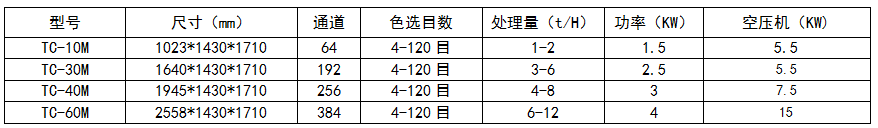

Industrial color separator (quartz sand, ore, crystal, etc.) color separator parameters

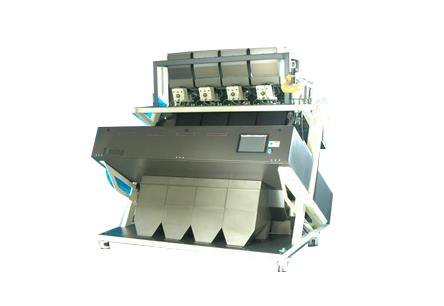

Industrial color sorters are widely used. Because the chute of the chute machine is designed according to the shape and size of the product, it can not be applied to products with large volume differences at the same time, or even selected cleanly. The cleaning rate is high. Crawler color sorter uses belt transmission, which is smooth and stable, and does not bounce. It is convenient for color identification, with high cleaning rate and small carry out ratio. At the same time, the processing capacity is also closely related to the variety of raw materials, the proportion of impurities contained and the required selection accuracy. Selection rate refers to the percentage of the amount of impurities selected from the raw grain in the total amount of impurities contained, also known as color separation accuracy. In order to improve the stability of the equipment, in addition to using high-stability light sources and high-quality imaging lenses, we should also adopt corresponding control technologies to compensate for the impact of environmental changes on the color sorter, and automatically adapt to different grain sources and impurity conditions, so that the color sorter can always keep in the best working state.

Download Center

Download Center Video Center

Video Center (86)0411-87625211

(86)0411-87625211