With the continuous development of China's economy, the people's living standard and quality are constantly improving, and the dietary structure has changed. Large consumption varieties such as rice and flour can no longer meet people's consumption needs. People are more and more interested in green food, health food and rare products. Coarse cereals will be recognized by more and more people because of their nutritional, health and green characteristics, which is of great significance for the development of coarse cereals. So there was a color sorter for cereals.

The color sorter equipment for coarse cereals can be widely used in agriculture, food industry, tea industry, industry, etc., effectively improving the quality of selected materials, increasing their added value, and ensuring the safety of food and use. The wide popularization and use of the color sorter for miscellaneous grains has replaced the large and tedious manual screening work, greatly speeding up the screening speed and working efficiency, and is more effective than manual screening. The value of grains and cereals after color selection by the color sorter will increase after impurities are removed. It is a new generation of artificial intelligence color sorting equipment for grain processing and agricultural machinery, and a good helper for farmers to screen and become rich.

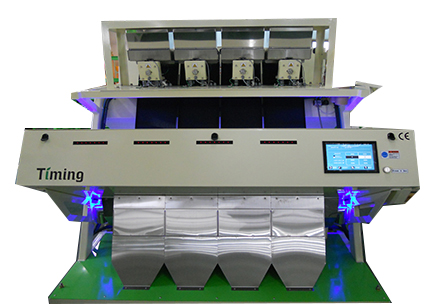

The color sorter is a high-tech photoelectric integrated mechanical equipment that automatically divides the heterochromatic particles in granular materials according to the difference of material colors by using optical equipment. The working principle of Taihe photoelectric color sorter is that the selected objects enter the machine from the feed hopper at the top of the machine, and the materials are evenly distributed to the object trough through the vibration of the vibration device. The selected materials slide down the trough to the sorting room at an accelerated speed.

The color and shape information of the material is obtained by CCD sensor in the sorting room The CCD camera transmits the data information to the processor of FPGA+DSP architecture. The processor distinguishes the defective materials in the normal materials through an efficient image processing algorithm, and then controls the high-frequency solenoid valve device to blow the defective materials into the receiving waste cavity, while the normal materials continue to fall into the finished product cavity of the receiving hopper, so as to eliminate the defective materials.

Download Center

Download Center Video Center

Video Center (86)0411-87625211

(86)0411-87625211