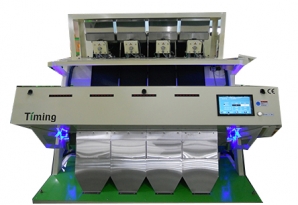

Fluorite, also known as fluorite, is the main source of fluorine in industry and one of the 20 important non-metallic mineral raw materials in the world. Fluorite, also called calcium fluoride, is a common halide mineral. It is a compound. Its component is calcium fluoride, and it is an important mineral for extracting fluorine. Only the deep processing and fine processing of ore products and seeking for quality breakthrough are the way out. It will be particularly important to use the fluorite color sorter. This article shows you how to select a fluorite color sorter from the four main systems.

1、 Photoelectric system

The photoelectric system consists of light source, background plate and sensor. The light source and camera are the eyes of the color selection "robot". The higher the resolution of the camera, the more accurate the material judgment and the higher the accuracy of color selection under the premise of the electronic control system. Therefore, when selecting the ore color sorter, you can ask the manufacturer about the camera resolution and the light source used.

2、 Electric control system

The electronic control system is composed of signal conditioning module, timing module and microcomputer control equipment. The electronic control system is the brain of the color sorting "robot", which is responsible for unified analysis and conversion of the materials seen by the naked eye and sending instructions to enable the sorting system to perform accurate sorting. The software system is the key to determine the throughput of color sorter. The running speed of the software is not enough, and the processing speed cannot keep up with it, which will lead to the problem of reducing the output precision or increasing the output precision. When selecting the ore color sorter, ask whether the software is independently developed. In the experimental analysis, you should check whether the operation accuracy and speed can meet your own material requirements.

3、 Feeding system

The feeding system is mainly composed of hopper, vibrator and chute. The most important part is the selection of the chute. At present, most of the chute color sorters on the market use hard aluminum alloy materials to make the chute. When selecting the chute ore color sorter, you must ask the manufacturer what material the chute is made of. You can ensure that the wear of the chute is within the controllable range, reduce the replacement frequency of the chute, and extend the service life of the color separator. In order to improve the production efficiency.

4、 Sorting system

The separation system of fluorite color sorter is mainly composed of finished product, inferior tank, spray valve and air source. The sorting system is the two hands of the color sorting "robot". After receiving the command from the brain, it will instruct both hands (spray valve) to blow the defective product into the defective container to achieve classification effect. When selecting the ore color sorter, you can see whether the jet valve is a six in one or nine in one jet valve or a single alloy valve. In the process of mass production, the damage of injection valve is caused by overload. In terms of durability, cost consideration and easy replacement, the valve is far inferior to alloy valve.

Download Center

Download Center Video Center

Video Center (86)0411-87625211

(86)0411-87625211