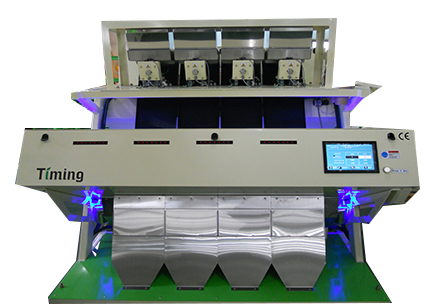

The miscellaneous grain color sorting machine is suitable for various types of miscellaneous grains in granular, flake or block form, mainly achieving precise sorting based on the color differences, shape characteristics and impurity types of the materials. The following are the commonly applicable types of miscellaneous grains and sorting scenarios:

1、 Grains and miscellaneous grains

Wheat, corn, rice

Sorting requirements: Remove moldy grains (such as corn scab), heterochromatic grains (black embryo grains in wheat, yellow grain grains in rice), stones, soil blocks, weed seeds (such as wild oats in wheat), etc.

Characteristics: The particles are large and require equipment with large-sized channels and high-speed processing capabilities. Some models can identify internal spoilage (such as corn cob mold damage) through near-infrared detection.

Sorghum, barley, millet

Sorting requirements: Remove broken grains, insect infested grains, immature grains (light color), and other grains mixed in (such as weed seeds in barley).

Features: Sorghum grains come in a variety of colors (red, white, yellow) and require a color sorter to accurately identify subtle color differences within the same color range.

Oats, buckwheat, quinoa

Sorting requirements: Remove empty shells, discolored grains (such as black grains in buckwheat), and impurities (such as sand particles and straw debris) to ensure the cleanliness of the finished product.

Characteristics: The particles are small and irregular in shape, requiring a high resolution camera (such as 2048 pixels or more) to avoid omission.

2、 Beans and miscellaneous grains

Soybeans, mung beans, red beans, black beans

Sorting requirements:

Soybeans: Remove mold spots, insect eyes, broken petals, and impurities (such as soil lumps and metal debris), distinguish different varieties (such as soybeans and green beans).

Green beans/red beans: Remove discolored grains (such as yellow grains in green beans and light red grains in red beans), stones, and grass seeds to ensure color consistency.

Black beans: Screen out particles with poor glossiness, damaged skin, or uneven color.

Characteristics: The color contrast of beans is obvious, suitable for visible light color sorting machine, but attention should be paid to the high-speed sorting accuracy of small particles such as mung beans (the error rejection rate should be ≤ 2%).

Peas, chickpeas, cowpeas

Sorting requirements: Remove insect infested particles (surface holes), cracked particles, and other mixed beans (such as stones or discolored beans in peas).

Characteristics: Some beans (such as chickpeas) have rough surfaces and require adjustable light source angles to avoid reflective interference with recognition.

3、 Oil based miscellaneous grains

Peanuts, sunflower seeds, sesame seeds

Sorting requirements:

Peanuts: Remove moldy grains (contaminated with Aspergillus flavus), damaged grains, discolored seeds (such as white and black seeds), stones, and peanut shell fragments.

Sunflower seeds: Screen out empty shells, flattened seeds, and insect infested seeds to distinguish different varieties (such as black melon seeds and white melon seeds).

Sesame: Remove impurities (such as grass seeds, sediment), and discolored grains (black or brown grains in white sesame).

Features: Sesame seeds are very small (about 2-3mm in diameter) and require equipment with micrometer level recognition capabilities. Some high-end models use microscope level cameras.

Rapeseed, flaxseed, perilla seed

Sorting requirements: Remove immature particles (light color), moldy particles, and impurities (such as straw and dust) to ensure oil yield and quality.

Characteristics: Small particles and high oil content, requiring smooth and anti stick connections in equipment channels to avoid material accumulation affecting sorting efficiency.

4、 Special miscellaneous grains and dry goods

Goji berries, red dates, longan (dried)

Sorting requirements:

Goji berries: Remove black fruits, moldy fruits, stems, and impurities, and grade them according to color depth (such as special grade fruits and ordinary fruits).

Red dates/dried longan: Remove insect infested fruits, cracked fruits, and discolored fruits (such as brown ones in red dates), and screen for uniformly sized particles.

Characteristics: The surface of dry materials may have wrinkles or gloss differences, requiring equipment light sources to illuminate from multiple angles to avoid misjudgment of shadows.

Lotus seeds, water chestnuts, Job's tears

Sorting requirements: Remove broken particles, discolored particles (such as green core residues in lotus seeds and black particles in Job's tears), and impurities (such as broken lotus seed shells).

Features: Some materials (such as lotus seeds with shells) need to be screened by shape first, and then sorted by color, which can be combined with multi-stage sorting equipment.

Nuts (such as walnuts, almonds, pistachios)

Sorting requirements: Remove empty shells, damaged kernels, moldy particles (such as Aspergillus contamination of walnuts), and impurities (such as shell debris).

Characteristics: Shell nuts need to distinguish between shell color and kernel color, and kernels need to be detected for internal mold (near-infrared technology is more effective).

5、 Other miscellaneous grains and processing scenarios

Starch based miscellaneous grains (such as dried sweet potatoes and cassava)

Sorting requirements: Remove burnt particles, discolored blocks (such as black spots in dried sweet potatoes), and impurities (such as sediment and debris).

Spices (such as Sichuan pepper, pepper, star anise)

Sorting requirements: Remove moldy particles, debris (such as branches and leaves), and discolored particles (such as black seeds in peppers).

Characteristics: Materials such as Sichuan peppercorns contain oil and are prone to sticking, requiring equipment with anti sticking material design (such as a feeder with adjustable vibration frequency).

By-products of miscellaneous grain processing

Impurities such as broken grains in corn processing and impurities in soybean meal can be screened twice by a color sorter to improve the utilization rate of by-products.

Summary of Applicable Scope

The core applicable condition of the coarse grain color sorter is that there are differences in color, gloss, or spectral characteristics between the material and impurities. Regardless of particle size and shape, as long as they can be distinguished through optical detection, sorting can be achieved. In practical applications, it is necessary to select the matching equipment configuration based on the specific material characteristics (such as sensor type, channel size, sorting speed, etc.), and if necessary, the manufacturer can be requested to provide customized sorting solutions.

Download Center

Download Center Video Center

Video Center (86)0411-87625211

(86)0411-87625211