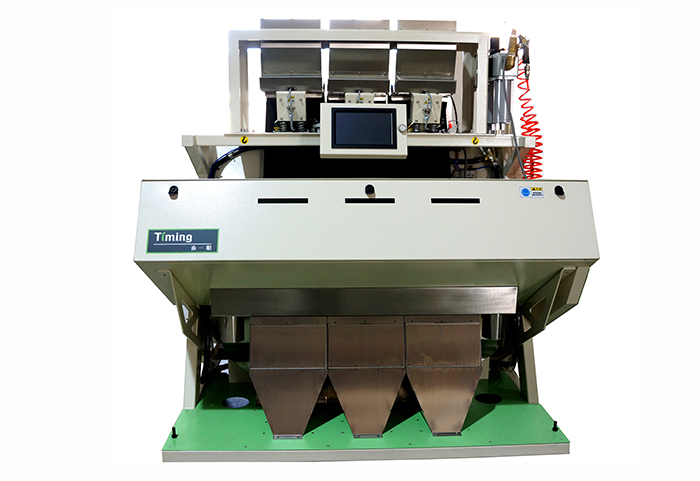

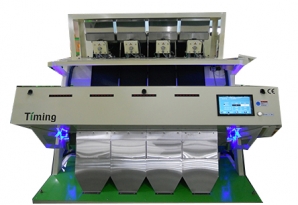

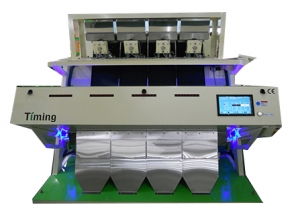

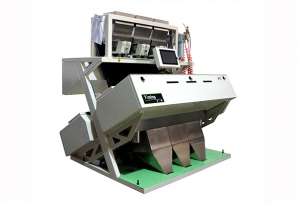

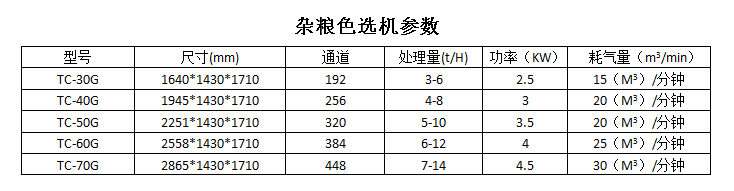

According to the difference of optical characteristics of materials, it is an equipment that uses photoelectric technology to automatically sort out different colored particles in granular materials. Photoelectric color sorter is an effective sorting equipment used for quality detection and grading of bulk materials, which is widely used in grain, food, pigment chemical industry and other industries. At present, photoelectric color separators of foreign brands occupy the main share in the domestic market. In recent years, photoelectric color separators independently developed in China have also begun to be gradually applied. As a typical mechatronic system, the research and development of the photoelectric color separator control system is not only the main aspect of the innovative design of the color separator, but also the key technical aspect that determines whether the developed color separator can obtain excellent performance. The color separation accuracy (the ratio of the weight of the authentic material and the material before the color separation of the selected material containing different color particles, expressed as a percentage) and the color separation rejection ratio (the ratio of the weight of the different color particles of the rejected material and the weight of the authentic material after the color separation of the material) are generally measured under the condition that the content of the different color particles is less than 2% and the flow rate is rated, and are related to the type, color Density.

Download Center

Download Center Video Center

Video Center (86)0411-87625211

(86)0411-87625211