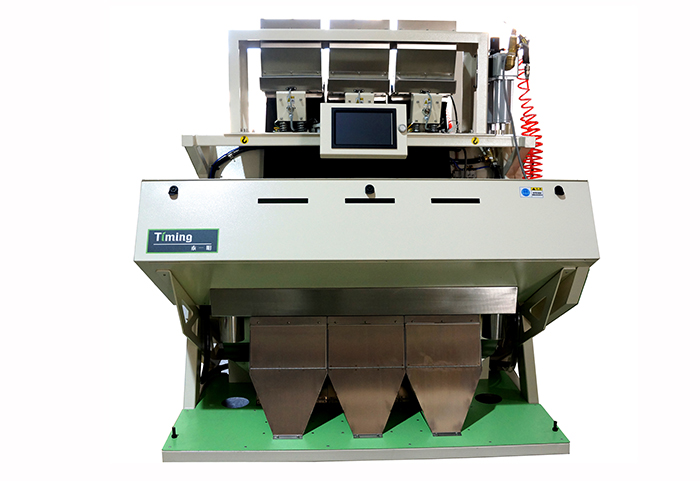

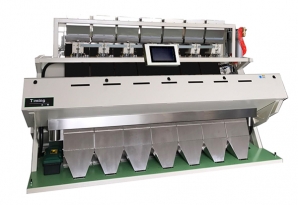

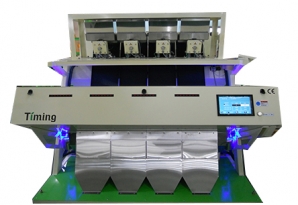

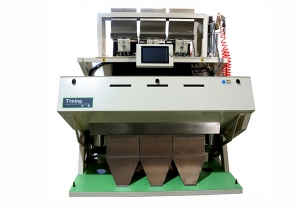

The main components of the corn color sorter are: feed hopper, vibrating feeder, chute slide, light source, background plate, CCD detection lens, discharge bin and air nozzle. Feeding system: it is composed of feeding hopper, vibrating feeder and chute slide. The corn materials to be sorted enter the vibrating feeder from the feed hopper, and the materials are automatically arranged into continuous current bundles through the vibrating and guiding mechanism. After being accelerated through the chute, they fall to the detection area of the photoelectric sorting at a constant speed, so as to ensure that the materials are clearly presented in the optical sorting and spraying area. In addition to the function of providing raw grain to be selected for the color separator, the feeding system can also control the output of the color separator. By adjusting the flow control board of the feed hopper and the vibration amount of the vibrating hopper, the output of the color separator per unit time can be controlled. Due to the large corn particles, jumping will inevitably occur after falling from the vibrating feeder to the chute channel, which will cause crowded stacking of corn when rolling in the channel, resulting in misjudgment of CCD lens. Therefore, a shockproof cover made of shock-absorbing material should be installed above the channel to weaken the corn jumping.

Download Center

Download Center Video Center

Video Center (86)0411-87625211

(86)0411-87625211