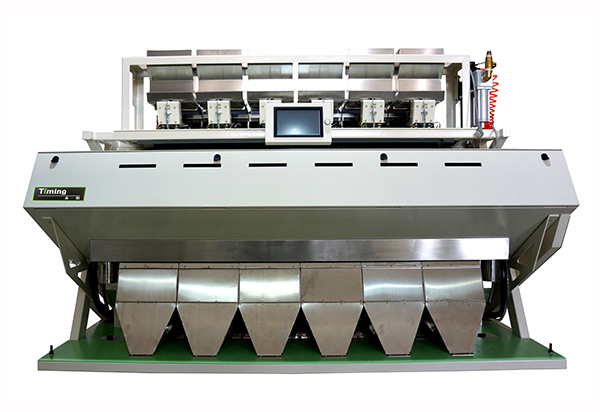

The rice color sorter can be divided into two types, one-way and two-way, in terms of detection structure, and two types, one-time selection and two-time selection, in terms of technology. Most of the old color sorters use one-way detection, which only observes the materials from one direction. Particles with disease spots on the back or particles covered when materials overlap cannot be detected and are missed. Therefore, it is not perfect in principle. Because this form of color sorter only uses one sensor for each slide, it observes the total optical signal in the whole slide range and cannot distinguish the respective colors of several rice grains or wheat grains flowing down at the same time in one slide. The rice color sorter is an effective sorting equipment used for the quality detection and classification of bulk materials, which is widely used in grain, food, pigment chemical industry and other industries. At present, photoelectric color separators of foreign brands occupy the main share in the domestic market. In recent years, photoelectric color separators independently developed in China have also begun to be gradually applied. Photoelectric color sorter is a typical mechatronic system.

Download Center

Download Center Video Center

Video Center (86)0411-87625211

(86)0411-87625211